Category:Blue Pullman

1960: Blue Pullman, on the cover of Meccano Magazine, October 1960 [image info]

1960: "New Pullman Services, Diesel Pullman, High Speed Luxury Travel", poster [image info]

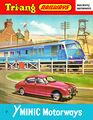

1964: Tri-ang Railways / Minic Motorways catalogue cover, showing a Jaguar car racing against a Blue Pullman [image info]

The "Blue Pullmans" were sets of distinctively blue double-engined diesel Pullman trains that ran on the British Rail network between 1960 and 1973.

Although often associated with BR Western Region (which had three eight-car sets), as an extension of the old GWR's reputation for grandness, BR London Midland Region also had two six-car sets, sometimes referred to as "the Midland Pullmans". These were transferred to the WR in around ~1966.

As with some other small-scale rail experiments, a lack of interchangeability and the need for specialised maintenance led to this small batch of trains being scrapped, after BR's introduction of new first-class carriages based on the "Mk2" carriage design.

1960 description:

excerpts:

Diesel Luxury Pullman Expresses

AS a notable part of the B.R. modernisation plan, de-luxe Pullman diesel-electric multiple-unit train sets of entirely new type have been introduced on the London Midland and Western Regions. ... They are finished externally in striking Nanking blue and white, and are beautifully equipped internally to a standard equalling, if not surpassing, anything of their type in the world. They feature a complete air-conditioning system, adjustable reclining seats in first class cars and an advanced standard of seating throughout in centre-corridor saloons with tables. Double-glazed windows have venetian blinds between, and there is a remarkable absence of noise. Novel, wide gangways between the cars afford freedom from oscillation, and there is exceptionally complete kitchen and pantry accommodation, lighting, etc.

The 6-car Midland Pullman carries first class passengers only from Manchester, Central to London, St. Pancras, in the morning, returning in the evening on overall timings less than 3¼ hrs. ... The northbound 85-minute schedule for 99 miles, averaging 70 m.p.h., is the fastest in Britain. ...

Two W.R. sets each of 8 cars, providing first and second class accommodation, and named the Birmingham Pullman and Bristol Pullman respectively operate twice each way. ...

The power cars at each end contain a 1,000 h.p. 12-cyl. diesel engine coupled to a main electric generator designed to supply traction current at between 1,250 and 1,700 amperes, as well as auxiliary generators feeding the lighting, heating and air-conditioning, refrigeration and other comprehensive equipment. They also have some seating accommodation, guard's and luggage compartments.

— , R.A.H. Weight, , Railway Notes, , Meccano Magazine, , October 1960

Official specifications

PULLMAN DIESEL EXPRESS SERVICES

THE BRITISH TRANSPORT COMMISSION, as part of the Modernisation Plan, has decided to introduce deluxe Pullman Diesel trains between important business centres.

On the Western Region, these new trains will run between Wolverhampton (Low Level), Birmingham (Snow Hill), Solihull and Learnington Spa (General) and London (Paddington), also between Bristol (Temple Means) and Bath Spa and Paddington. As far as practicable, their schedules have been designed to meet the travel requirements of the business executive.

Built at the Birmingham Works of the Metropolitan-Cammell Carriage & Wagon Company, Ltd., on the multiple-unit principle with diesel-electric traction, these new Pullman trains are of an entirely new design, incorporating air-conditioning and many recent technical developments in vehicle and bogie construction. The vehicles are of the saloon, centre vestibule type, and special consideration has been given to the exterior styling and to the interior decor.

Meals and refreshments will be served throughout the trains, to the traditional high Pullman standards.

Details of the different cars are as follows:

End Cars

- Type – Motor Car, containing Driver's Compartment, Engine Compartment, Generator Compartment, Guard's Compartment, Passenger Saloon.

- Seating – 18 Second Class.

- Dimensions – Length over body ends 66 ft. 5½ in.

- Bogie centres 46 ft. 6 in.

- Bogie Wheelbase 9 ft. 6 in.

Traction motors are fitted to the bogies at the opposite end of the vehicle to the Driver's Cabs.

2nd and 7th Cars

- Type – Parlour Car (Second Class) containing Passenger Saloon, two lavatories, luggage space.

- Seating – 42 Second Class.

- Dimensions – Length over body ends 65 ft. 6 in.

- Bogie centres 46 ft. 6 in.

- Bogie Wheelbase 8 ft. 6 in.

Traction motors are fitted to the bogies adjacent to the motor cars.

A Rolls-Royce auxiliary diesel engine, driving a Stone's alternator is mounted on the underframe of each of these cars. This equipment provides the power for the air-conditioning, heating, lighting and 24v. battery charging, etc., on the whole train.

3rd and 6th Cars

- Type – Kitchen Car, containing Passenger Saloon, pantry, kitchen, staff compartment, lavatory, luggage space, staff lavatory.

- Seating – 18 First Class.

- Dimensions – as Second Class Parlour Car.

4th and 5th Cars

- Type – Parlour Car (First Class), containing Passenger Saloon, two lavatories, 1ugage space.

- Seating – 36 First Class.

- Dimensions – as Second Class Parlour Car.

- Total length of train over buffers 545 ft. 1 in.

- Total First Class seats 108

- Total Second Class seats 120.

Details of Power Equipment

- Main Engines (2)-1,000 H.P. 12 cylinder N.B.L./M.A.N. Diesel.

- Main Generator (2) — G.E.C. Type WT.882.

- Traction Motors (8) — G.E.C. Type WT.361.

- Air Compressors (2) — Westinghouse D.H.C.5 Motor Driven

- Auxiliary Engine (2) — Rolls-Royce 8 cylinder Diesel.

- Auxiliary Alternator (2) — Stone's 133 KVA, 400V, 3 phase 50 cycles.

Every vehicle in the train is of all-steel welded construction, the trailer cars being designed on the stressed skin principle, whilst the power cars have box girder type underframes. These underframes are fabricated throughout from steel plate welded together, the whole frame being made in several parts which were stress relieved prior to the final assembly of the frame.

The bogies are also of welded construction, the tubular frames of the leading and motor bogies being fabricated from special steel pressings.

The Westinghouse Self-Lapping Electro-pneumatic Brake with Speed Control

The brake combines under the control of a single handle, the following:

- (a) The Electro-pneumatic brake, which is an electrically controlled compressed air brake giving simultaneous and uniform application and release on all vehicles in the train.

- (b) The Automatic brake providing emergency application of the brake by either the driver, guard or passengers, or if the train should part.

- (c) The High Speed brake, which is an automatic feature superimposed on the Electro-pneumatic and Automatic brakes, permitting retardation from a high speed to be maintained during a stop, at rates nearer the safe limit of adhesion than would be possible with a single stage brake, by making available higher brake forces at suitable speeds.

Air Conditioning System

The passenger saloons of all cars in the train are fitted with a fully comprehensive air-conditioning system.

This system controls the temperature and humidity within established comfort limits regardless of outside conditions, supplies the correct amount of outside air, ensures that the distribution of air inside the coach is controlled and draughtfree, and eliminates dirt and dust both of external and internal origin.

The advantages to the passenger are that the atmosphere inside thetrain is always draughtless, clean and comfortable; the upholstery, fittings and service appointments are always clean, and the heat insulation of the sealed vehicle results in effective insulation against external noises.

These conditions are achieved by a refrigerating and heating installation in each car which can be accurately controlled within a range to suit the detailed requirements of the particular service.

Air cooling and dehumidification are accomplished by means of a mechanical refrigeration system. The compressor and condenser units of the system are mounted on the underframe of the cars and the evaporator units are mounted in the car ceiling. Heating is achieved by means of electric heating elements at floor level, and in the air-conditioning unit in the ceiling.

The temperature conditions within the car are thermostatically controlled, the transition from operation of cooling to heating equipment or vice versa, being automatically effected. Three different temperature settings for heating and cooling are provided which the attendant can select by a manual control switch within the car.

Circulation of air in the car is created by centrifugal fans in the ceiling mounted air-conditioning unit. Outside and re-circulated air is drawn through filters, mixed, passed over the cooling coils of the refrigerating equipment, then over a group of electric heating elements and finally into the air delivery ducts, from whence it is delivered into the car.

If cooling is called for the refrigeration equipment is made active, this also having the effect of condensing out excessive moisture in the air supply. If heating is required the electric heating elements are made active, supported by the electric elements fitted at floor level.

The necessary power to operate this equipment, and also the fluorescent lighting fitted to all passenger saloons, is provided by one of the auxiliary generating sets mounted under the Second Class Parlour Cars. This power is passed down the train by means of heavy jumper cables between coaches. In normal weather conditions the auxiliary engines at each end of the train will be used separately on alternate journeys, but in extremely cold weather both sets can be used, the second set providing additional floor heat.

When the trains are standing in terminal stations an external supply will be connected to the train by means of the jumpers to avoid running the auxiliary engine. This is to obviate the inconvenience which would be caused to passengers on the platform by the noise of the auxiliary engine running in a confined space. The supply will be disconnected and the auxiliary engine started shortly before the train is due to leave.

Details of Colour Schemes, Fittings and Finishes

Exterior

The bodyside and end panels are painted Nanking Blue (Medium Blue); the roofs are grey; the windows are secured by black rubber mouldings and the window surrounds and the spaces between windows are painted white, forming a continuous white panel on each vehicle. The word "Pullman" is painted below this panel at the end of each of the trailing vehicles, and at the non-driving end of each power car. The Pullman coat-of-arms is shown on the white panel above these inscriptions. The bogies are painted black, whilst the underframe and the equipment mounted on the underframe is painted aluminium.

The train name and destination stations are displayed on roller blinds through glazed panels let into the bodysides of each end car, the mechanism being operated from inside the Guard's compartment.

Interior

All passenger saloons throughout the train, both First and Second Class, are of the centre corridor type, tables are fitted between opposite facing seats, two seats being situated on one side of the gangway and single seats on the other side. Each set of seats and tables is positioned centrally against a large window, giving all passengers an unrestricted view.

Individual aircraft type seats are provided in both classes, tip-up seats being fitted to provide easy access. Controls are fitted in the arms of the seats in the First Class saloons to adjust the angle of the seat back, and to allow the whole seat to be moved forward for dining. All windows are double-glazed to prevent condensation, heat losses, and to provide sound insulation. Small Venetian blinds are fitted between the two sheets of glass, and these blinds can be raised, lowered, and the angle of the slats adjusted by the passengers by means of small control handles fitted at the sides of the windows. Press buttons are also fitted below each window to enable the passengers to call the attendant. Operation of these buttons illuminates a green indicator light over the appropriate table, and also an indicator in the corridor of the Kitchen Car. The lights can be cancelled by the attendant by the operation of a button fitted on each table leg. Modern table lamps are also fitted to each table and passenger switches are provided for their operation.

General lighting in all saloons is provided by fluorescent tube fitted behind a fluted perspex screen about 2 ft. wide, running along the centre of the ceiling. Metal mouldings fitted to each side of this panel conceal the air delivery ducts through which the air from the air-conditioning unit is passed into the saloon.

Loudspeakers connected to the public address system are placed behind grilles which are spaced out along one side of the ceiling above the parcel racks. This system is wired to a central control point, from where the Conductor will make any announcements to the passengers.

Solid parcel racks run the whole length of the vehicle and small circular incandescent light fittings are provided on the underside of the rack over each table. The walls or body sides are covered with Lanide or Vynide (leathercloth) mounted on foam plastic, giving a luxurious padded effect. Stainless steel grilles are fitted over the electric heating elements at the base of the bodyside, padded leathercloth being fitted to the whole of the bodyside, and the lower surfaces of the parcel rack in one continuous sweep. The ceiling between the parcel racks and the lighting panels is made from a special plastic panel having fine black stripes approximately ¼in. apart, running longitudinally on a pale grey background.

An unusual feature incorporated in the hinged doors at the end of the passenger saloons is the window in the upper half of the door. This is glazed with specially prepared glass which has alternate vertical strips of mirror and clear glass.

Overall carpets are fitted throughout, whilst the floor itself is carried on the underframe with rubber mountings. The floor of the passenger entry vestibules at the ends of the vehicles is covered in coir matting which is carried in zinc lined wells.

The gangways between cars have been developed for air-conditioned vehicles and incorporate special rubber bellows and clipping arrangements to ensure that they are air-tight. The interiors incorporate hinged and sprung flaps covered with padded Lanide which allow the necessary relative movement between the vehicles, and at the same time always present a continuous Lanide-covered wall. The overall effect is a big improvement on any gangways on existing vehicles.

Toilets are provided at both ends of the Parlour cars, and at one end of the Kitchen cars. These toilets contain the usual fittings including a mirror with concealed lighting and a special tap over the hand-basin which will deliver a predetermined quantity of water at the temperature selected by the passenger. The interior and exterior walls of the toilets are covered with various shades of plastic panel, and the floors are multi-coloured ceramic tiles.

Opposite the toilets in the end vestibules are double-tiered slatted luggage racks made from aluminium extrusions, the front rail being rubber covered to prevent damage to passengers' luggage. The draught screen adjacent to the vehicle entry door is made from specially toughened glass.

The decorative schemes in all Second Class saloons are identical, whereas two different schemes have been used in the First Class accommodation. Details of the materials used in all schemes are as follows:

First Class

(Scheme 1)

- Passenger Saloon Walls. - Lanide, French grey.

- Passenger Saloon Partitions and Doors. — Rio Rosewood Veneer.

These partitions are a polished rich dark brown, and those at both ends of the Parlour Car and at the Kitchen end of the Kitchen Car incorporate brightly coloured inlaid murals of a most modern and striking design.

- Carpet. — "Cortina Kingfisher" (irregular blue trace on a black background).

- Seats. — The seats are upholstered in a specially woven wool/nylon fabric having narrow vertical stripes alternately red and navy blue. The seat back and arm pads are covered in grey hide, and trim is in matching grey Lanide, and the arm sides and pedestal are covered in black Lanide.

- Table Tops. — Lanide, French grey.

- Metal Fittings. — (Window frame, table edge, parcel rack, rack light fittings) Anodised satin finish pale gold.

- Lavatories. -

- (a) Wall behind washbasin — Clover Pink Hopscotch matt plastic (small pink pattern on white ground). Other three walls — Pale Pink Filigree matt plastic. Outside walls — Red Tapestry design matt plastic.

- (b) Wall opposite window — Flame Carousel plastic (small red and grey triangular pattern).

- Other three walls---Grey Filigree plastic.

- Outside walls—Pale Blue Tapestry design matt plastic.

First Class

(Scheme 2) This, in general, is similar to scheme 1 but with the following exceptions: the passenger saloon partitions and doors being finished with Macassar Ebony veneer, the carpet "Cortina Cardinal" (irregular red trace on black background) and seating upholstery colours being changed to blue and navy blue vertical stripes.

Second Class

- Passenger Saloon Walls. — Grey Vynide with a fine basket-weave pattern.

- Passenger Saloon Partitions. — Jester pattern plastic (blue diamond pattern on white ground).

- Partition Doors. — Blue-grey linen pattern plastic.

- Carpet. — Devon Weave (Random Red rectangles on black ground).

- Seats. — The seats are upholstered in a blue woven material with a thin vertical black stripe. The seat back and arm pads are covered in grey hide; trim in matching grey Lanide, and the arm sides and pedestal are covered in black Lanide.

- Table Tops. — Lanide, French grey.

- Metal Fittings. — Anodised satin finish silver.

- Lavatories. — Wall opposite window — Chinese Blue Hopscotch plastic (fine regular pattern on blue/green ground).

- Other three walls--Payne's Grey Filigree plastic.

- Outside walls—Blue-grey, linen pattern plastic.

The pantries and kitchens, together with the corridor adjacent to these compartments are panelled in pale grey linen pattern plastic. The floors are pink composition flecked with white with a diamond pattern metal grid as reinforcement. All working surfaces are stainless steel, and most of the fittings are enamelled white.

The following equipment is fitted:

Pantry

- Refrigerator.

- S.S. sink unit comprising main sink, electrically heated plate racks, etc. steriliser, strainer.

- Ascot heater.

- Various cupboards, shelves, bottle racks, etc.

- Extractor fan.

Kitchen

- Refrigerator with ucep freeze capacity.

- Sink unit as pantry.

- Ascot heater.

- Double gas stove.

- Double eye-level grill.

- Hot cupboard.

- Racks, cupboards, etc.

- Extractor fan.

- Large serving hatch into corridor

All cooking is by Propane Gas.

The interior of the Driving cabs are painted grey, with a white ceiling and black control desk.

The equipment fitted in the cab includes the following:

- Adjustable seats for driver and second man.

- Master controller, incorporating reversing handle and power handle.

- Driver's brake controller.

- Deadman's treadle under control desk. Two warning horn controllers.

- Gauges and instruments to indicate:

- Brake cylinder pressure.

- Main reservoir and brake pipe pressure (Duplex gauge).

- Speed in M.P.H.

- Generator current (Ammeter).

- Western Region A.T.C. equipment modified to work with Westinghouse Brake.

Control panel on desk incorporating:

- Control switch.

- Engine start push button.

- Engine stop push button.

- Overload reset push button. Engine stop indicator light.

- Alarm indicator light.

- E.P. Brake indicator light.

- Auxiliary heat switch.

Switch and indicator light panel incorporating:

- Instrument light switch.

- Instrument lights dimmer.

- Headcode light indicators and switches.

- Two windscreen wipers with controls.

- Loudaphone for communication with the Guard.

- Handbrake with through train indicator light.

- Cab heating controls including a fresh air/recirculating selector.

- Indicator lights for: High speed brake and auxiliary engine shut-down.

- High speed brake test button.

- Electric cooker.

- Hand lamp socket and switch.

— , BR (Western Region), and The Pullman Car Co. Ltd., , Introduction of PULLMAN DIESEL EXPRESS SERVICES between WOLVERHAMPTON & BIRMINGHAM AND LONDON (PADDINGTON): ALSO BRISTOL and LONDON (PADDINGTON), , 1960

External links

- Met-Camm 6/8-car Blue Pullman (railcar.co.uk)

- Blue Pullman – A Fascinating Failure? (twsmedia.co.uk)

- Blue Pullman Rides Again (focustransport.org) – 6th August 2020

video:

Pages in category ‘Blue Pullman’

The following 2 pages are in this category, out of 2 total.

Media in category ‘Blue Pullman’

The following 12 files are in this category, out of 12 total.

- Blue Pullman Diesel Motor Cars, powered and unpowered, R-555 and R-556 (TR 1963).jpg 3,000 × 1,166; 1.58 MB

- Blue Pullman Parlour Car, Tri-ang R-426 (TR 1964).jpg 2,467 × 904; 972 KB

- Blue Pullman Train Set, Tri-ang RS-52 (TR 1964).jpg 4,592 × 1,431; 2.79 MB

- Blue Pullman, Meccano Magazine cover (MM 1960-10).jpg 813 × 1,200; 743 KB

- Diesel Pullmans (TRM 1960-12).jpg 1,051 × 1,800; 1.12 MB

- Luxury on the Line, Blue Pullman Train Set (TriangMag 1965-04).jpg 2,352 × 3,000; 2.23 MB

- Midland Pullman Kitchen Car, box lid (Kitmaster 32).jpg 2,200 × 751; 1.47 MB

- Midland Pullman Kitchen Car, instructions (Kitmaster No32).jpg 1,838 × 2,200; 1.39 MB

- Midland Pullman Power Car, box lid, flat (Kitmaster 31).jpg 2,400 × 1,082; 2.28 MB

- The Blue Pullman, train set, box lid (Tri-ang Railways RS52).jpg 3,000 × 2,170; 5.79 MB

- The Midland Pullman, article (TriangMag 1965-04).jpg 800 × 511; 355 KB

- Triang Railways, catalogue front cover (TRCat 1964).jpg 2,324 × 3,000; 4.89 MB