Category:Jetex rocket motors: Difference between revisions

m (BTMM Eric moved page Jetex to Category:Jetex rocket motors) |

(+Address) |

||

| Line 12: | Line 12: | ||

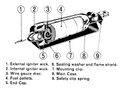

{{Quotation2|<h4>How Jetex motors work</h4> | {{Quotation2|<h4>How Jetex motors work</h4> | ||

Solid Fuel Charge (4) is ignited by the Plastic Igniter Wick (2), the coiled end of which is held against the face of the charge by a Gauze Disc (3) The gas is compressed in the main case (8) and forces its way out through the jet at supersonic speed, producing thrust. The end cap (5) is held by spring (9), and acts as a safety valve. If the jet were to clog, the gas escapes via the end cap. }} | Solid Fuel Charge (4) is ignited by the Plastic Igniter Wick (2), the coiled end of which is held against the face of the charge by a Gauze Disc (3) The gas is compressed in the main case (8) and forces its way out through the jet at supersonic speed, producing thrust. The end cap (5) is held by spring (9), and acts as a safety valve. If the jet were to clog, the gas escapes via the end cap. }} | ||

==Addresses== | |||

* '''Wilmot, Mansour & Co., Ltd.''', Totton, Southampton, England | |||

{{Links}} | {{Links}} | ||

Revision as of 14:43, 14 March 2018

| Toy Brands and Manufacturers |

|---|

Jetex rocket motors |

| 1948 - |

The Jetex rocket motors were designed for model aircraft, but were sometimes also fitted to model cars and other toy and model vehicles.

Characteristics

The popularity of the Jetex system in the 1950s was due to how well the system had been thought out. The propellant (guanidine nitrate) was comparatively slow-burn, with a comparatively cool exhaust and a decent burn time, which meant that a model aircraft didn't have to deal with severe stresses or have to have extravagant firefproofing, and the reusable shell could be made of aluminium or aluminium alloy. The casing design included a sprung safety release valve so that the rocket wasn't prone to exploding if something went wrong, and the sealed fuel capsules had their own internally factory-fitted fuses, removing another possible cause of unreliability. The Jetex capsules were ignited with a short external fuse, which then lit the internal coiled fuse, which then in turn ignited the solid fuel – the user couldn't accidentally light the fuel directly without the factory-set time delay.

The manufacturers also made of point of mentioning that the guanidine nitrate propellant was supplied to them by ICI, eliminating the worry of small-batch production producing variations in performance.

Overall, the Jetex system was easy to use, reliable, and comparatively safe, and its predictability meant that makers were confident about making model vehicles (even cars!) that could be sold as "Jetex-compatible" – knowing that the behaviour of the customer's unit would be pretty much the same the same as that of their test model.

1967 promotional text:

How Jetex motors work

Solid Fuel Charge (4) is ignited by the Plastic Igniter Wick (2), the coiled end of which is held against the face of the charge by a Gauze Disc (3) The gas is compressed in the main case (8) and forces its way out through the jet at supersonic speed, producing thrust. The end cap (5) is held by spring (9), and acts as a safety valve. If the jet were to clog, the gas escapes via the end cap.

Addresses

- Wilmot, Mansour & Co., Ltd., Totton, Southampton, England

External links

- Jetex.org community fan site (jetex.org)

- Welcome to Mike's flying scale model pages: Jetex/Rapier powered models (ffscale.co.uk)

Subcategories

This category has the following 3 subcategories, out of 3 total.

Pages in category ‘Jetex rocket motors’

This category contains only the following page.

Media in category ‘Jetex rocket motors’

The following 52 files are in this category, out of 52 total.

- Atom 35 rocket motor, Jetex (Hobbies 1966).jpg 1,046 × 1,014; 336 KB

- Avro 707A Delta, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,418; 340 KB

- DeHavilland Venom, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,180; 427 KB

- DH 110 Sea Vixen, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,328; 323 KB

- Douglas F4D Skyray, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,241; 375 KB

- Eagle Book of Spacecraft Models (Hobbies 1968).jpg 1,802 × 1,721; 981 KB

- Gloster Javelin model aircraft, Jetex 50C (Hobbies 1966).jpg 2,175 × 1,639; 745 KB

- Gloster Javelin, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,397; 578 KB

- Gnat Glider, for Jetex, cover image crop (KeilKraft 1969).jpg 1,200 × 566; 576 KB

- Grumman Panther, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,273; 381 KB

- Hawker Hunter, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,274; 436 KB

- Helicopter, Jetex (BPO 1955-10).jpg 1,230 × 689; 163 KB

- How Jetex Motors Work (Hobbies 1967).jpg 3,000 × 1,245; 932 KB

- Interceptor aircraft, Jetex (BPO 1955-10).jpg 1,144 × 753; 183 KB

- Javelin aeroplane, Jetex (Hobbies 1967).jpg 1,549 × 1,316; 445 KB

- Jet Car, Jetex (Hobbies 1967).jpg 1,927 × 1,385; 557 KB

- Jet Hydroplane, Jetex (Hobbies 1967).jpg 1,851 × 1,138; 531 KB

- Jetex 50 Motor (KeilKraft 1969).jpg 911 × 1,200; 251 KB

- Jetex 50c rocket motor (MM 1967-07).jpg 2,277 × 1,607; 1.16 MB

- Jetex advert, Hobbies (MM 1967-07).jpg 3,000 × 2,033; 2.55 MB

- Jetex Car and Boat, Gamages (MM 1950-11).jpg 2,197 × 673; 474 KB

- Jetex Cars and Boats, Gamages (MM 1950-08).jpg 2,828 × 3,000; 1.9 MB

- Jetex F-102 aircraft, advert (USA 1954).jpg 844 × 1,200; 324 KB

- Jetex Kits and Power Kits (Hobbies 1966).jpg 860 × 1,200; 975 KB

- Jetex Models (Hobbies 1967).jpg 3,000 × 1,028; 1.02 MB

- Jetex Power and Accessories (Hobbies 1967).jpg 2,297 × 3,000; 2.37 MB

- Jetex rocket motor, cross-section diagram (Hobbies 1967).jpg 1,728 × 1,264; 445 KB

- Jetex toys and model kits (GaT 1956).jpg 1,001 × 1,600; 296 KB

- Jetex Type 50C rocket motor(Hobbies 1966).jpg 1,767 × 1,249; 688 KB

- KeilKraft for Jetex 50 Motors (KeilKraft 1969).jpg 1,024 × 767; 110 KB

- KeilKraft Jetex-powered Flying Saucer (HH 1952).jpg 892 × 668; 152 KB

- KeilKraft Jetex-powered range (HH 1952).jpg 800 × 163; 23 KB

- MIG 15, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,133; 337 KB

- Model Racing Car, Jetex, Selfridges (MM 1949-08).jpg 1,643 × 2,200; 926 KB

- North American F-86 Sabre, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,118; 390 KB

- PAA-Loader, Jetex (MM 1967-07).jpg 2,620 × 1,320; 1.13 MB

- Race Car, Jetex (BPO 1955-10).jpg 890 × 615; 127 KB

- Racing Car, Jetex (Hobbies 1966).jpg 1,928 × 666; 340 KB

- Racing Car, Jetex (Hobbies 1967).jpg 1,617 × 1,519; 691 KB

- Scorpion rocket motor, Jetex (MM 1967-07).jpg 2,465 × 1,482; 1.12 MB

- Sharky Jetex model aircraft, Hamleys (MM 1954-06).jpg 1,413 × 902; 353 KB

- Skyjet 50, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,009; 346 KB

- Speed boat, Jetex (BPO 1955-10).jpg 1,147 × 698; 217 KB

- Speed Boat, Jetex (Hobbies 1966).jpg 1,903 × 893; 459 KB

- Speed Boat, Jetex (Hobbies 1967).jpg 1,511 × 1,184; 468 KB

- Supermarine Attacker, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,193; 326 KB

- Supermarine Swift model aircraft, Jetex 50C (Hobbies 1966).jpg 2,393 × 1,643; 1.09 MB

- Supermarine Swift, for Jetex 50, KeilKraft (KeilKraft 1969).jpg 2,200 × 1,584; 349 KB

- Swift aeroplane, Jetex (Hobbies 1967).jpg 2,889 × 1,619; 995 KB

- Wren aeroplane, Jetex (Hobbies 1967).jpg 1,778 × 1,470; 492 KB

- Wren model aeroplane, Jetex Atom 35 rocket motor (Hobbies 1966).jpg 1,703 × 797; 339 KB