Category:Brighton Locomotive Works

| Brighton Station |

|---|

Brighton Locomotive Works |

|

Station | History | CabRoad | GoodsTunnel | LocoWorks | Greenway | ToyMuseum |

0-6-0 Terrier-Class locomotive LBSCR 40 "Brighton", built at Brighton Locomotive Works in 1878 [image info]

0-6-0 Terrier-Class locomotive LBSCR 41 "Piccadilly", built at Brighton Locomotive Works in 1877. [image info]

0-4-2 LBSCR D1 Class locomotive 232, Lewes, built at Brighton Works in 1884 [image info]

0-8-0 tank locomotive A950, built at Brighton Works in 1929 [image info]

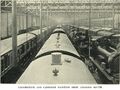

Two Brighton Works locos leaving Victoria Station [image info]

"Building Engines by the Seaside", lecture by Gerry Collins, 2002 [image info]

Brighton Locomotive Works (or just, Brighton Works) was one of Britain's earliest steam locomotive manufacturing facilities, and is reckoned to have been responsible for producing over twelve hundred engines, including the E2 Class second-series design used in the illustrations for "Thomas the Tank Engine".

The site of the works can be seen if you exit the Museum, turn left, and look at the newer buildings on Trafalgar Street to the immediate left of the Museum. These occupy a space that was previously railways sidings and the engine works.

As a nod to the site's heritage, many of the roads and walkways in the area are named after railway engineers and designers, or have other railway associations.

Brighton Locomotive Works had a difficult history, due to the geographical awkwardness of a restricted site cut into the side of a hill, which made lack of space a constant problem.

1847-1869: John Craven

When John Chester Craven took over as Locomotive Superintendent in 1847, his reign, while not exactly disastrous, created acute long-term problems for the Works. Craven's natural inclination, as with many of the early locomotive engineers, was to be a "tinkerer" ... to treat each new locomotive or loco batch as an exciting opportunity for improvement or experimentation, with the result that the number of official locomotive classes that the Works had to support was supposed to be greater than seventy. Trying to maintain servicing knowledge and spares for more than seventy loco types must have been a nightmare. In March 1853, locomotive No. 10 exploded at the beginning of the shift, killing the three people who in the cab. The locomotive had recently been serviced, and the enquiry found that the loco had been so extensively patched and modified that there was little possibility of finding out what had really happened, and while Craven wasn't blamed, questions were probably asked about how the Works had been run under his leadership.

Craven's biggest achievement seems to have been persuading the civic authorities to allow him to remove the hill of chalk rubble on the lower side of the line that had been created when the hillside had been cut into to create space for the station and the main line. While the town was originally against this, they relented when Craven said that his alternative was to remove the works (and its jobs) to a more convenient site further up the line. Completely removing the chalk hill, a little at a time, took many years ... but once it had gone, Craven's successor was able to put the cleared space to good use.

It's perhaps notable that while his successors have roads on the old Works site named after them: Stroudley Road and Billinton Way – nobody seems to have named anything after Craven.

1870-1889: The Stroudley Years

William Stroudley (1833-1889) took over the Locomotive Engineer position after Craven retired, and stayed in post until his death in December 1889.

Stroudley immediately set about a process of simplifying and standardising the stock of locomotives and locomotive parts, reducing the range to six classes with as many interchangeable parts as possible. This didn't just reduce the space requirements for storing spare parts, spares could now be more produced more proactively knowing that they would definitely be used, and the easier supply of spares meant that more repairs could be made with drop-in replacements available from stock, speeding up turnaround times and reducing the space needed for locos waiting to be repaired.

Stroudley also encouraged the specialisation of skills – with standardisation, instead of making one spare part for the stores, one could have an identical batch made, ideally by the same person who made the last batch, and who (hopefully) knew that part better than the other people in the Works. Standardisation didn't just reduce costs and space and time, it could also improve quality.

The Stroudley era produced the "Terriers" (the LB&SCR Class A1/A1X), lightweight 0-6-0 tank locomotives named after places on the LBSCR railway network

1890-1904: The Billinton Years

Billinton took over in January 1890, almost immediately after Stroudley's death.

Billinton was extremely capable and had a wide range of experience at different employers, including a spell of perhaps four years as Stroudley's assistant at the LB&SCR from 1870, followed by a similar role at the Midland Railway. This meant that Billinton already had an in-depth understanding of the Brighton Works site and company culture, but also had first-hand knowledge of how things worked at other railways.

Gallery (1903)

World War One

During the Great War, the loco works was used for munitions production, and this, combined with the amount of time it took to turn the space back into a loco works afterwards, just made the Brighton backlog even larger.

1923 Grouping, and electrification

The creation of the Southern Railway in the 1923 grouping of British railway companies provided an excuse for reassessing and reorganising the railway's facilities, and since the railway was planning on electrifying much of its track, the need to build and service large numbers of steam locomotives was going to become less important. This resulted in a lot of the plant being moved to the works at Eastleigh and Ashford.

The Brighton site became increasingly turned over to the maintenance of the new EMUs ("Electric Multiple Units"). The fact that the EMU driver units had the same profile as the carriages allowed the creation of a new "drive through" washer similar to those used for automatically washing cars, that could clean the entire train in one go.

World War Two

Slated for closure, the desperate need for more wartime loco production resulted in the resurrection of the works, whose output now included the distinctive "Austerity" Q1 Class. This new phase in the works' history ended with the permanent cessation of locomotive fabrication in 1962.

The Isetta Works

For a while, the site – essentially a factory on stilts, on a hillside, only easily accessible by rail – was used for building Isetta bubble-cars for the UK market, with all the raw materials entering the site by rail, and the completed cars leaving on flatbed wagons (pointing sideways).

In the museum

The museum foyer has a display area devoted to Brighton Locomotive Works, including paintings.

External links

Subcategories

This category has the following 6 subcategories, out of 6 total.

B

- Brighton Greenway (1 P, 8 F)

E

- E. Burrows (3 P, 3 F)

I

- Isetta bubble-cars (6 P, 1 F)

S

- Schools-Class locomotives (5 P, 10 F)

T

- Terrier Class locomotives (2 F)

Pages in category ‘Brighton Locomotive Works’

The following 33 pages are in this category, out of 33 total.

B

- Beachy Head locomotive (gauge 0)

- Bessemer locomotive LBSC 213 (gauge 0)

- Billington E2 tank locomotive 104 (Hornby R353)

- Blue Funnel, Merchant Navy Class locomotive, Southern 21C13 (Wrenn Railways W2278)

- BMW Isetta bubble-car, bright red, LTR 145 (Spot-On 118)

- BMW Isetta bubble-car, dark blue, JPO 113 (Spot-On 118)

- BMW Isetta bubble-car, dark red, LXQ 216 (Spot-On 118)

- BMW Isetta bubble-car, green, JPO 113 (Spot-On 118)

- BMW Isetta bubble-car, light mauve (Spot-On 118)

- BMW Isetta bubble-car, yellow, CMO 118 (Spot-On 118)

- Brighton locomotive 915 (ACE Trains)

- Brighton locomotives

- Budleigh Salterton locomotive nameplate

C

L

S

Media in category ‘Brighton Locomotive Works’

The following 48 files are in this category, out of 48 total.

- Another view of the Paint Shop, Brighton Works (TRM 1903-04).jpg 3,000 × 2,146; 1.36 MB

- Bassett-Lowke, Merchant Taylors 910, gauge 0 (BL-MR 1937-11).jpg 1,526 × 2,226; 610 KB

- Belgravia, LBSCR 201, 2-4-0 locomotive (TRM 1903-04).jpg 3,000 × 1,534; 937 KB

- Boiler Shop, Brighton Works (TRM 1903-04).jpg 3,000 × 2,007; 1.44 MB

- Brighton 915 Schools-Class loco (ACE Trains).jpg 800 × 600; 285 KB

- Brighton Greenway, April 2016.jpg 2,000 × 1,334; 1.89 MB

- Brighton locomotive SR 915 (RWW 1935).jpg 2,200 × 781; 1.26 MB

- Brighton Works and LBSCR, Billinton interview (TRM 1903).jpg 2,200 × 1,442; 656 KB

- Brighton, Terrier Class locomotive LBSCR 40 (RWW 1935).jpg 3,000 × 1,391; 2.67 MB

- Building Engines by the Seaside, lecture by Gerry Collins (2002-05-09).jpg 1,416 × 2,000; 408 KB

- Bulleid Leader.jpg 700 × 280; 47 KB

- Carriage Erecting Shop, Brighton Works (TRM 1903-04).jpg 3,000 × 2,323; 1.96 MB

- Dieppe, LBSCR 490, 2-2-2 locomotive (TRM 1903-04).jpg 3,000 × 1,245; 691 KB

- Duchess of Fife, LBSCR 43 (TRM 1903-04).jpg 3,000 × 1,990; 1.29 MB

- Erecting Shop, Brighton Works (TRM 1903-04).jpg 3,000 × 2,037; 1.42 MB

- Eton 900 locomotive detail, Hornby.jpg 800 × 600; 381 KB

- Eton locomotive 900 (MM 1937-08).jpg 1,583 × 729; 286 KB

- Fairlight, LBSCR 331, 0-2-2 locomotive (TRM 1903-04).jpg 2,979 × 2,121; 552 KB

- Gladstone loco 214 (Miller Swan).jpg 1,024 × 574; 389 KB

- Harrow Schools Class loco, box artwork (Rosebud Kitmaster No5).jpg 2,200 × 698; 1.37 MB

- Harrow Schools Class loco, instructions (Rosebud Kitmaster No5).jpg 1,693 × 2,500; 1.74 MB

- Hickstead, LBSCR 571, 0-6-2 tank locomotive (TRM 1903-04).jpg 3,000 × 1,890; 1.37 MB

- Hornby E420 Eton Locomotive (1939- catalogue).jpg 2,269 × 999; 278 KB

- Hurst Green, LBSCR 465, 0-6-2 tank locomotive (TRM 1903-04).jpg 3,000 × 1,496; 1.08 MB

- Jenny Lind, 3.5-inch gauge steam model (Bill Hinchley).jpg 2,000 × 1,334; 514 KB

- Leader-Class steam locomotive model.jpg 1,024 × 603; 333 KB

- Lewes, LBSCR D1-Class locomotive 232 (RWW 1935).jpg 3,000 × 1,435; 2.72 MB

- Locomotive and Carriage Painting Shop, Brighton (TRM 1903-04).jpg 3,000 × 2,253; 1.6 MB

- Locomotive tools, sculptures, Brighton Greenway.jpg 2,000 × 1,334; 1.73 MB

- Märklin Stephenson gauge 1 locomotive.jpg 640 × 480; 187 KB

- Piccadilly, Terrier Class locomotive (RWW 1935).jpg 3,000 × 1,488; 3.09 MB

- Pillars belonging to the old Brighton Locomotive Works (Brighton Greenway).jpg 1,800 × 1,352; 1.58 MB

- Schools Class locomotive, lineart (Kitmaster No5).jpg 628 × 432; 101 KB

- Seaford, LBSCR 282, 2-2-2 locomotive (TRM 1903-04).jpg 3,000 × 1,703; 1.12 MB

- Southern 900 Eton locomotive (HBoT 1938).jpg 3,286 × 2,476; 1.04 MB

- Southern A950 tank locomotive (WBoR 14ed).jpg 3,000 × 1,358; 2.05 MB

- Southern Belle leaving Victoria Station, postcard (F Moore).jpg 2,500 × 1,600; 3.3 MB

- Standard 48ft bogie brake van, Brighton Works (TRM 1903-04).jpg 1,800 × 1,062; 471 KB

- Stephenson 329 locomotive, gauge 1 (Marklin).jpg 1,200 × 900; 561 KB

- Stephenson Tank Locomotive Southern 329, 4-6-4, Märklin TK1020 (MarklinCRH ~1925).jpg 2,104 × 1,115; 962 KB

- Tank locomotive SR 329 Stephenson, Märklin MTK 1020 1021 (Bonds 1932-2ed).jpg 2,500 × 789; 812 KB

- The Boiler Shop, Brighton Locomotive Works (E Burrows ~1955).jpg 1,200 × 976; 854 KB

- The Erecting Shop, Brighton Locomotive Works (E Burrows ~1955).jpg 1,200 × 947; 823 KB

- The Foundry, Brighton Locomotive Works (E Burrows ~1955).jpg 1,200 × 969; 625 KB

- Third Class Coach, LBSCR, built 1852 (TRM 1903-04).jpg 1,800 × 1,752; 791 KB

- Tri-ang Wrenn Model Railways, catalogue front cover (TWCat 1971).jpg 1,424 × 2,000; 554 KB

- Truscott, LBSCR 364, 0-4-4 tank locomotive (TRM 1903-04).jpg 3,000 × 1,707; 1.4 MB

- Turning and Machine Shop, Brighton Works (TRM 1903-04).jpg 3,000 × 2,280; 1.69 MB